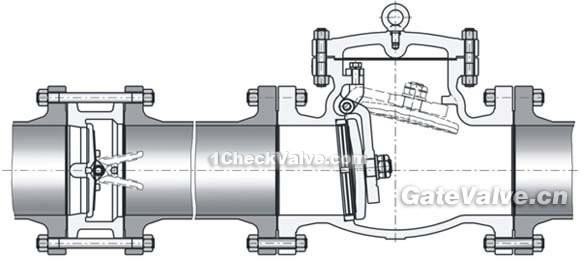

The comparison of wafer check valve and flange swing check valve

H76 wafer type bivalve butterfly check valve H44 flange univalve swing check valve

| structure type | H76 wafer type bivalve butterfly check valve | H44 flange univalve swing check valve |

| Water hammer pressure | Water hammer pressure, disc have a short trip, close valve spring assisted closed fast speed | Water hammer pressure, disc longer journeys, it takes a long time to close |

| H76 Water hammer pressure only H44 type 1/2-1/5 | ||

| Size and weight | A short length of structure, small volume, light weight, easy installation, the valve handling, storage and piping layout, and can save material and reduce cost | The structural length is very long, large volume, weight is very stupid |

| H76 The type of structure length H44 only 1/4 ~ 6, H76 type 1 / weight only H44 type 1/4-1 in 10 | ||

| Fluid resistance | A small resistance and fluid flow resistance coefficient ζ for 2.6 ~ 0.7, with the increase of valve size, fluid resistance coefficient decreases | A small resistance and fluid flow resistance coefficient ζ 1.3 ~ 3, but in low-pressure conditions cannot be completely open, disc, fluid resistance. Fluid resistance with the valve size increases |

| installation | Can be installed horizontally or vertically, light weight, need for valve setting bearings | Can be installed horizontally or vertically, large diameter valve weight, need to install bearings |

| Open pressure | Open valve, pressure is in small pressure differentials can fully open | Open valve, pressure in the larger pressure differentials can fully open |

| Reliability | The valve for the whole structure, simple and compact, valve closed wallop, water hammer pressure small small, long service life, high reliability valve | Check valve closes the huge impact and water hammer pressure easily |