Welding Power Station Swing Check Valve

manufacturer: Kaiweixi Valve Group Co., LTD.

E-mail: Yannie@kaiweixi.com

Tel: +86(577)67038872

Mob: +86 189 6779 6135(WeChat Same Account)

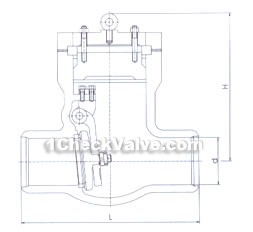

product drawing

Welding power station swing check valves

Usages

Welding (GB) Power Station Swing Check Valve is used in the pipelines of petroleum, chemical, water, fire power plant and other systems that nominal pressure is PN20.0 ~ 32.0MPa, work temperature ≤ 540 ℃ ( in which 57170V operating temperature is 570 ℃). Applicable medium: water, oil, steam and so on.

Structural features

1. The product design and manufacture according to the provisions of the E101 and JB/T3595-93 standards, with reasonable structure, excellent performance, beautiful shape.

2. The middle cavity uses pressure self-tight sealing structure, the higher medium pressure, the better the sealing performance.

3. The both ends of branch pipes are butt welded, to adapt to different requirements.

4. The disc and the seat sealing surface use stellite cobalt-based hard alloy bead welding, with wear-resistance, high temperature resistance, good anti-abrasion performance, long service life.

5. High temperature and pressure-resistance components are made of high-quality heat-resistant alloy steel, with safety and reliablity, stable performance, long service life.

Dimensions & constructral diagram

Welding power station swing check valve constructral diagram

The materials of main parts

| body | WCB、25 | 2Cr1MoV | WC6 | WC9 |

| bonnet | 25 | 12CrMoV | ||

| disc,seat | 25 heap STL cobalt-based hard alloy | 12CrMoV STL cobalt-based hard alloy | ||

| sealing ring | enhanced flexible graphite | |||

Main external and connection dimensions

| type | Nominal diameter (mm) | Main external and connection dimensions | Weight (kg) | |

| L | H | |||

| H64Y-200 | 50 | 350 | 200 | 50 |

| 65 | 430 | 282 | 57 | |

| 80 | 470 | 325 | 65 | |

| 100 | 600 | 350 | 80 | |

| 175 | 900 | 440 | 180 | |

| H64Y-320 | 125 | 900 | 409 | 170 |

| 225 | 1000 | 550 | 415 | |

| 300 | 1370 | 680 | 1200 | |

| 350 | 1370 | 745 | 1638 | |