Power Station Exhaust Check Valve

manufacturer: Kaiweixi Valve Group Co., LTD.

E-mail: Yannie@kaiweixi.com

Tel: +86(577)67038872

Mob: +86 189 6779 6135(WeChat Same Account)

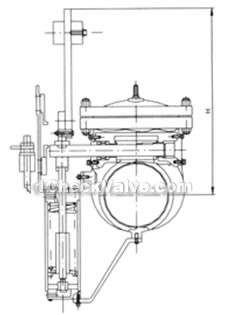

product drawing

Power station exhaust check valves(pic1)

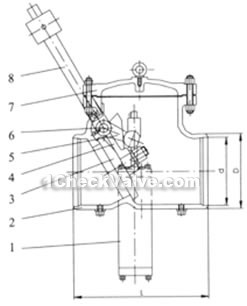

Power station exhaust check valve(pic2)

Usages

The valve is used in power plants or thermal power plant exhaust system, or other systems of steam and water pipes that are non-corrosive media, to prevent the pressure sudden drop of the internal steam turbine when the steam tubine suddenly rejects load, the steam extraction pipe and the heater inside steam back into the steam turbine to cause the blade broken, destroyed turbogenerator accidents and to prevent the water impact accident caused by heater system pipe leakage that water from the extraction pipeline leak into the turbine, in order to protect the safe operation of steam turbine. As a preventing media reflux device, the valve can be cloed quickly and tightly in 0.5 seconds, to ensure when water level of the feedwater heater appears extra high, the pneumatic device components will quickly separate the machines after receiving the liquid counter-current signal, and give the maximum protection for the steam turbine, or exhaust system.

Structural features

1.Sealing surface bead welding Crl3 is stainless steel or cobalt-based hard alloy, with good abrasion resistance, stable and reliable sealing performance

2.When the medium flows forward, the down cavity of the cylinder intakes air, affact with heavy hammer together, to make the disc in a fully open position. When the medium flows reversely, the cylinder piston down cavity rapid release pressure, the disc close quickly in 0.5 seconds.

3.Hammer affect on the pin by adding the rod and fork, to balance the rocker’s heavy torque, prevent the water hammer phenomenon. When the medium flows forward, it will help to open the valve, and keep the valve smooth in the operation and reduce the vibration.

Dimensions & constructral diagram

Power station exhaust check valve constructral diagram(pic1)

Power station exhaust check valve constructral diagram(pic2)

The materials of main parts

| No. | part name | carbon steel type (C) | alloy steel (f) |

| 1 | cylinder | A105 | A105 |

| 2 | body | WCB | WC6 |

| 3 | disc | WCB | WC6 |

| 4 | rocker | WCB | WC6 |

| 5 | shifting fork | WCB | WCB |

| 6 | pin | 2Crl3 | 304 |

| 7 | bonnet | WCB | WC6 |

| 8 | plus long-rod and heavy hammer | WCB | WCB |

Main performance and specifications

| test pressure (MPa) | nominal pressure(MPa) | ||||||

| 1.6 | 20 | 2.5 | 4.O | 5.O | 6.4 | 10.0 | |

| shell intensity test | 2.4 | 3.0 | 3.5 | 6.0 | 7.5 | 9.6 | 15.0 |

| sealing test | 1.8 | 2.2 | 2.8 | 4.4 | 5.5 | 7.1 | 11.0 |

Applicable scope

| product type | suitable temperature (℃) | applicable medium |

| carbon steel (C) | ≤425 | steam,water,etc |

| alloy steel(I) | ≤550 | non-corrosive medium |