Flange Lift Check Valve

manufacturer: Kaiweixi Valve Group Co., LTD.

E-mail: Yannie@kaiweixi.com

Tel: +86(577)67038872

Mob: +86 189 6779 6135(WeChat Same Account)

product drawing

Flange lift check valves

Structural features

The main structural characteristics of flange lift check valve: 1, exquisite selection, in line with domestic and foreign standards, with comprehensive high quality of materials. 2, flange lift check valve seal pair is mateched advanced and reasonable, the disc and seat sealing surface adopt iron-based alloy or stellite cobalt-based hard alloy build up welding, with wear-resistance, high temperature resistance, corrosive resistance, good anti-abrasion performance, long service life. 3, flange lift check valve is designed and manufactured according to GB/T12235 national standard. 4, it can be used with a variety of flange standards and flange sealing types, to meet the various engineering needs and user requirements. 5, full range of body materials, gaskets can be matched reasonably based on the actual working conditions or the user requests. It can be applied to all kinds of pressure, temperature and medium conditions. According to user requirements, we can design and manufacture check valves with different structural forms and connection forms, for supporting the use of various equipment. Flange lift check valve is used in the pipelines of oil, chemical, fire station and other working conditions that the nominal pressure is PN1.6 ~ 6.4MPa, working temperature is -29 ~ 550 ℃. Applicable medium: water, oil, steam and so on.

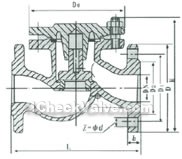

Dimensions & constructral diagram

Flange lift check valve constructral diagram

Performance and specifications

| type | nominal pressure PN(MPa) | test pressure(MPa) | suitable temperature(℃) | applicable medium | ||

| sealing | gas sealing | shell | ||||

| H41Y-25I | 2.5 | 2.75 | 0.6 | 3.75 | ≤550 | steam,water,oil,etc |

| H41Y-40I | 4.0 | 4.4 | 0.6 | 6.0 | ||

| H41Y-64I | 6.4 | 7.04 | 0.6 | 9.6 | ||

| H41Y-100I | 10.0 | 11.0 | 0.6 | 15.0 | ||

| H41Y-25P | 2.5 | 2.75 | 0.6 | 3.75 | ≤150 | weak corrosive medium |

| H41Y-40P | 4.0 | 4.4 | 0.6 | 6.0 | ||

| H41Y-64P | 6.4 | 7.04 | 0.6 | 9.6 | ||

| H41Y-100P | 10.0 | 11.0 | 0.6 | 15.0 | ||

The materials of main parts

| part name | body,bonnet,disc | body and disc sealing face | gasket | bolt | |

| material | I | Cr-Mo steel | hard alloy | steel strip asbestos winding gasket | Cr-Mo-V steel |

| P | Cr-Mo-Ti stainless steel | hard alloy | PTFE | stainless steel | |

Connection dimensions and weight

| nominal diameter DN(㎜) | dimensions (㎜) | weight (㎏) | ||||||||

| L | D | D1 | D2 | b | f | Z-фd | H | D3 | ||

| 15 | 130 | 95 | 65 | 45 | 16 | 2 | 4-ф14 | 100 | - | 5 |

| 20 | 150 | 105 | 75 | 55 | 16 | 2 | 4-ф14 | 105 | - | 7 |

| 25 | 160 | 115 | 85 | 65 | 16 | 2 | 4-ф14 | 115 | 110 | 9 |

| 32 | 190 | 135 | 100 | 78 | 18 | 2 | 4-ф18 | 120 | 120 | 10 |

| 40 | 200 | 145 | 110 | 85 | 18 | 3 | 4-ф18 | 140 | 135 | 15 |

| 50 | 230 | 160 | 125 | 100 | 20 | 3 | 4-ф18 | 150 | 150 | 20 |

| 65 | 290 | 180 | 145 | 120 | 22 | 3 | 8-ф18 | 160 | 175 | 25 |

| 80 | 310 | 195 | 160 | 135 | 22 | 3 | 8-ф18 | 175 | 200 | 32 |

| 100 | 350 | 230 | 190 | 160 | 24 | 3 | 8-ф23 | 200 | 230 | 57 |

| 125 | 400 | 270 | 220 | 188 | 28 | 3 | 8-ф25 | 230 | 273 | - |

| 150 | 480 | 300 | 250 | 218 | 30 | 3 | 8-ф25 | 265 | 330 | - |

| 200 | 600 | 360 | 310 | 278 | 34 | 3 | 12-ф25 | 300 | 365 | - |