ANSI Swing Check Valve

manufacturer: Kaiweixi Valve Group Co., LTD.

E-mail: Yannie@kaiweixi.com

Tel: +86(577)67038872

Mob: +86 189 6779 6135(WeChat Same Account)

product drawing

ANSI swing check valves

Introductions

The function of check valve is to prevent the media backflow in the pipeline. Check valves are automatic valves, the hoist part depends on the flow media power to open or close. Check valve is only used in the one-way flow pipelines, preventing the media backflows, and avoiding the accidents.

Our check valves are designed and manufactured by ANSI B16.34 standard. Varieties include: Swing check valve, lift check valves, lift vertical check valve; Class 150lB ~ 900Lb; NPS 1 "~ 28" Operating temperature -40 ~ 570 ℃; Body materials: WCB, WC1 , WC6, WC9, C5, CF3, CF8, CF3M, CF8M, etc.. Applicable medium: water, steam, oil, nitric acid, strong oxidizing medium and urea, etc. the valves are widely used in power plants, petroleum, chemical, pharmaceutical, food and other industries, can be directly matched with the imported equipments.

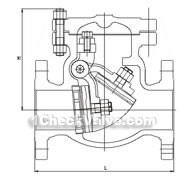

Dimensions & constructral diagram

ANSI swing check valve constructral diagram

Standard

| type | design and manufacture | face to face dimension | flange dimension | pressure-temperature | test-inspection |

| swing check valve | ANSI B16.34 | ANSI B16.10 | ANSI B16.5 | ANSI B16.34 | API |

| lift check valve | BS 1968 |

Test pressure

| nominal pressure PN (Lb) | intensity test | gas sealing test | gas sealing test | |||

| Mpa | Lbf/i n 2 | Mpa | Lbf/i n 2 | Mpa | Lbf/i n 2 | |

| 150 | 3.1 | 450 | 2.2 | 315 | 0.5-0.7 | 60-100 |

| 300 | 7.8 | 1125 | 5.6 | 815 | ||

| 600 | 15.3 | 2225 | 11.2 | 1630 | ||

| 900 | 23.1 | 3350 | 16.8 | 2440 | ||

The materials of main parts and performance

| body,bonnet,disc | stem | gasket | sealing face | working temperature ℃ | applicable medium |

| WCB | 2Cr13 | enhanced flexible graphite 13Cr/ flexible graphite stainless steel/ acid-resistant asbestos serrated gasket | 13Cr STL body material nylon PTFE | ≤425 | water,steam,oil,nitric acid, acetic acid strong oxidation media urea |

| WC1 | ≤450 | ||||

| WC6 | ≤540 | ||||

| WC9 | ≤570 | ||||

| C5 C12 | ≤540 | ||||

| CF8 | 304 | ≤200 | |||

| CF8M | 316 | ||||

| CF3 | 304L | ||||

| CF3M | 316L |

Main technical dimensions

| nominal diameter DN | 150Lb、10K | 300Lb、20K | 600Lb | 900Lb | |||||||||

| in | mm | L(RF) | H | weight (kg) | L(RF) | H | weight (kg) | L(RJ) | H | weight (kg) | L(RJ) | H | weight (kg) |

| 2 | 50 | 203 | 165 | 17 | 267 | 190 | 28 | 292 | 210 | 32 | 372 | 335 | 120 |

| 2 1/2 | 65 | 216 | 175 | 25 | 292 | 205 | 33 | 330 | 230 | 42 | 422 | 370 | 165 |

| 3 | 80 | 241 | 190 | 29 | 318 | 220 | 45 | 356 | 255 | 60 | 384 | 300 | 115 |

| 4 | 100 | 292 | 215 | 50 | 356 | 245 | 70 | 432 | 295 | 110 | 460 | 340 | 180 |

| 6 | 150 | 356 | 265 | 85 | 444 | 295 | 150 | 559 | 365 | 220 | 613 | 425 | 400 |

| 8 | 200 | 495 | 320 | 150 | 533 | 330 | 230 | 660 | 420 | 390 | 740 | 490 | 690 |

| 10 | 250 | 622 | 356 | 240 | 622 | 420 | 390 | 787 | 505 | 630 | 841 | 585 | 1020 |

| 12 | 300 | 698 | 415 | 350 | 711 | 480 | 520 | 838 | 545 | 870 | 968 | 655 | 1550 |

| 14 | 350 | 787 | 460 | 460 | 838 | 535 | 710 | 889 | 600 | 940 | 1038 | 710 | 2000 |

| 16 | 400 | 864 | 495 | 580 | 864 | 585 | 890 | 991 | 650 | 1100 | 1140 | 765 | 2500 |

| 18 | 450 | 978 | 590 | 690 | 978 | 615 | 1000 | 1092 | 735 | 1300 | 1232 | 810 | 3000 |