JIS Stop-Check Valve

manufacturer: Shanghai MeiYan Yi Pump & Valve Co., Ltd.

Eml: sales@1bengfa.com

Tel: +86 (21) 5640 2009

Mob: +86 138 1691 3072(WeChat Same Account)

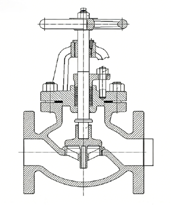

product drawing

JIS Stop-Check Valve

Overview

The JIS Stop-Check Valve is a multi-functional valve compliant with Japanese Industrial Standards (JIS), integrating the manual shut-off capability of a stop valve with the automatic backflow prevention function of a check valve. The valve body is typically made of cast iron, cast steel, or stainless steel. The valve disc is raised or lowered via handwheel rotation to achieve flow shut-off control, while the built-in check mechanism automatically prevents medium backflow when the valve is open.This valve strictly adheres to JIS standards such as JIS B2003 and JIS B2071, ensuring full compatibility with JIS piping systems in terms of pressure ratings, structural dimensions, and flange connections. It is specifically designed for marine vessels, Japanese industrial equipment, and related engineering projects that require both manual shut-off and automatic backflow prevention, providing dual assurance for process control and safety protection.

Features

1. Dual-function integrated design: Integrating the controllable shutoff function of the globe valve with the automatic anti-backflow function of the check valve simplifies pipeline design and equipment configuration, reducing installation points and potential leakage risks. 2. Strict compliance with JIS standards: The entire process of design, manufacturing, and inspection follows JIS specifications to ensure that the valves are fully compatible with the Japanese standard system in terms of dimensions, pressure ratings (such as JIS 10K/20K), flange connections (JIS B2220), and material requirements. 3. Reliable operation and good sealing performance: The stop section adopts a spiral lifting seal structure, ensuring smooth operation and reliable sealing; the check section relies on medium flow for automatic opening and closing, providing rapid response and effectively preventing backflow. 4. Compact structure and space-saving: The integrated design occupies less space than separately installed stop valves and check valves, making it particularly suitable for space-constrained applications such as ship engine rooms and compact equipment. 5. Easy maintenance and high interchangeability: The standardized design facilitates procurement and spare parts replacement within the Japanese standard system. The globe valve disc and check valve disc can be separately maintained or replaced, resulting in low maintenance costs.

Dimensions & constructral diagram

JIS Stop-Check Valve constructral diagram

Material of main parts

| NO. | Name | Material |

|---|---|---|

| 1 | Body | Cast Iron |

| 2 | Disc | Bronze Casting |

| 3 | Stem | Brass |

Performance Specification

| Item | Value | Unit |

|---|---|---|

| Nominal Pressure | 5K | Mpa |

| Shell Test Pressure | 0.75 | Mpa |

| Seal Test Pressure | 0.55 | Mpa |

| Suitable Temperature | ≤200 | ℃ |

Specification and dimensions

| Nominal Diameter (mm) | Overall Dimensions | Flange Connection Dimensions | |||||

|---|---|---|---|---|---|---|---|

| L | H | Do | D | D1 | b | n-d | |

| 50 | 220 | 274 | 160 | 155 | 120 | 20 | 4-Φ19 |

| 65 | 270 | 293 | 200 | 175 | 140 | 22 | 4-Φ19 |

| 80 | 300 | 302 | 200 | 185 | 150 | 22 | 8-Φ19 |

| 100 | 350 | 344 | 250 | 210 | 175 | 24 | 8-Φ19 |

| 125 | 420 | 387 | 280 | 250 | 210 | 24 | 8-Φ23 |

| 150 | 490 | 430 | 315 | 280 | 240 | 26 | 8-Φ23 |

| 200 | 570 | 502 | 355 | 330 | 290 | 26 | 12-Φ23 |