DIN Lift Check Valve

manufacturer: Shanghai MeiYan Yi Pump & Valve Co., Ltd.

Eml: sales@1bengfa.com

Tel: +86 (21) 5640 2009

Mob: +86 138 1691 3072(WeChat Same Account)

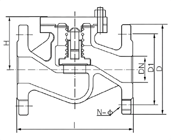

product drawing

DIN Lift Check Valve

Overview

The DIN Lift Check Valve is an automatic check valve designed and manufactured in strict compliance with German Industrial Standards (DIN), featuring a vertical lift structure. The valve body is typically constructed from materials such as cast iron, cast steel, or stainless steel, with its design conforming to DIN series standards (e.g., DIN 3352). The valve opens as the forward pressure of the medium lifts the disc and automatically closes under the combined action of the disc's own weight and reverse pressure.Specifically designed for horizontal pipelines, this valve offers tight sealing and a simple structure. It is suitable for applications involving water, steam, oil, and non-corrosive industrial media. As a fundamental component in DIN-compliant pipeline systems for chemical, heating, water supply, and drainage industries, it effectively prevents medium backflow.

Features

1. Strict DIN Standards Compliance

Fully compliant with standards such as DIN EN 12266 throughout the process, ensuring complete compatibility with German-standard pipeline systems in terms of pressure ratings, face-to-face dimensions, flange connections, and material requirements.

2. Reliable Sealing with Lift Design

Features a vertical lift disc design that ensures tight seating against the valve seat upon closure, providing excellent sealing performance and effectively preventing backflow of various media.

3. Stable Structure for Horizontal Installation

Specifically designed for horizontal pipelines, with strict installation orientation requirements. Its simple and robust structure ensures reliable operation.

4. Low Flow Resistance and Easy Maintenance

Offers an unobstructed flow path when fully open, resulting in minimal pressure loss. The straightforward internal structure facilitates easy inspection, cleaning, and maintenance.

5. Cost-Effective, Durable, and Highly Versatile

Provides reasonable manufacturing costs and a long service life. As a universal component in the DIN system, it simplifies procurement and replacement in European-standard projects.

Dimensions & constructral diagram

DIN Lift Check Valve constructral diagram

Material of main parts

| NO. | Name | Material |

|---|---|---|

| 1 | Body | Ductile Iron, Cast Steel |

| 2 | Disc | Rubber-Lined Carbon Steel |

| 3 | Bolting Components | Carbon Steel |

Performance Specification

| Performance Specification | ||

|---|---|---|

| Nominal Pressure | 1.6/2.5/4.0 | MPa |

| Shell Test Pressure | 2.4/3.8/6 | |

| Seal Test Pressure | 1.8/2.8/4.4 | |

| Suitable Temperature | ≤350 | ℃ |

Specification and dimensions

| DN | L (mm) | H (mm) | Kv | Weight (Kg) | ||

|---|---|---|---|---|---|---|

| PN16 | PN25 | PN40 | ||||

| 15 | 130 | 70 | 5.7 | 2.4 | 3.5 | 3.8 |

| 20 | 150 | 70 | 7.8 | 3.0 | 4.4 | 4.9 |

| 25 | 160 | 80 | 11.8 | 3.8 | 5.0 | 5.9 |

| 32 | 180 | 80 | 17.9 | 5.7 | 6.0 | 7.1 |

| 40 | 200 | 85 | 27.5 | 7.4 | 8.0 | 10.4 |

| 50 | 230 | 95 | 48.0 | 10.3 | 11.0 | 12.3 |

| 65 | 290 | 110 | 77.6 | 15.2 | 16.0 | 22.7 |

| 80 | 310 | 130 | 109.0 | 20.4 | 21.0 | 28.5 |

| 100 | 350 | 155 | 168.0 | 31.0 | 32.0 | 40.0 |

| 125 | 400 | 165 | 251.0 | 49.0 | 51.0 | 64.0 |

| 150 | 480 | 215 | 399.0 | 69.0 | 70.0 | 90.0 |

| 200 | 600 | 285 | 664.0 | 132.0 | 136.0 | 170.0 |

| 250 | 730 | 325 | 1017.0 | 198.0 | 218.0 | 240.0 |

| 300 | 850 | 365 | 1446.0 | 278.0 | 350.6 | 370.0 |